Pandemic or not, there is no time to sit back and relax because both (international) legislation and gathered experiences continuously result in making small adjustments to the design of our machines, not just to comply with the regulations but also to optimize the user experience.

A NEXT STAGE

Pandemic or not, there is no time to sit back and relax because both (international) legislation and gathered experiences continuously result in making small adjustments to the design of our machines, not just to comply with the regulations but also to optimize the user experience.

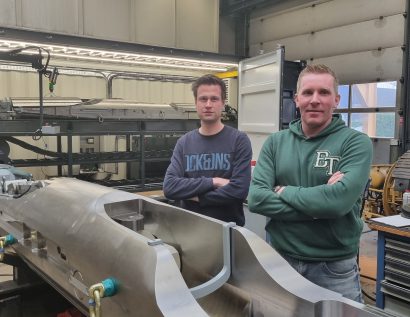

An example is this Maats BM06-24 that is not looking much different from the ones we built before but that in fact marks a big step in the evolution of our Maats bending machines. This because it is the first Maats bending machine that is equipped with an engine that complies with European emission regulations according to EC (NRMM) Stage V. This new engine means that our customers can use this machine on any jobsite in the world, even those with the most stringent emission regulations.

The machine has all the features that are standard to Maats bending machines: servo controlled levers, a beacon that indicates that the machine is in operation, the hydraulic connections for a bending mandrel and (for this machine) the ability to bend a 24”/609,6mm grade API 5L-X70 pipe with a wall thickness of over one inch. Like all Maats BM06-24 bending machines this new machine is also supplied with adaptors that allow the use of bending dies that normally are used in 06-20 bending machines, which means that the most expensive part of bending sets that are already owned still can be used!

The machine has been tried, tested and approved and is now awaiting the Maats livery before it can go to work, generating new customer feedback!

Click here to view all details

Other news

FINANCE DEPARTMENT: A CLOSER LOOK BEHIND THE NUMBERS

Mentoring mechanics: fostering talent and tradition at Maats Pipeline Professionals

Transitioning from Hand-drawn Sketch to Advanced Machinery – Insights from the Engineering Department

Climate neutral rental: how does it work, and what are the benefits?

Why frequent personal contact with customers and jobsites matters

Maats and Liebherr: A Successful Collaboration

Benefits of renting pipeline equipment at Maats

Providing a fixed rope

What are the benefits of an internal bending machine?